ABB och Kawasaki ska samarbeta om ”cobotar”

Två av världens största tillverkare av industrirobotar, svensk-schweiziska ABB och japanska Kawasaki, inleder ett samarbete för att utveckla ”cobotar” som kan arbeta tillsammans med människor.

– Robotar som samarbetar, särskilt de med två armar som är kapabla till mänskliga interaktioner, kan i hög grad bidra till samhället och hjälpa världen att klara av arbetskraftsbrist och en åldrande arbetskraft, säger Kawasakis robotchef Yasuhiko Hashimoto enligt ett pressmeddelande.

ABB och Kawasaki ska fortsätta att på egen hand utveckla och bygga robotar men ska bland annat arbeta tillsammans med att ta fram en industristandard för ”cobotar”.

bakgrund

Cobot

Wikipedia (en)

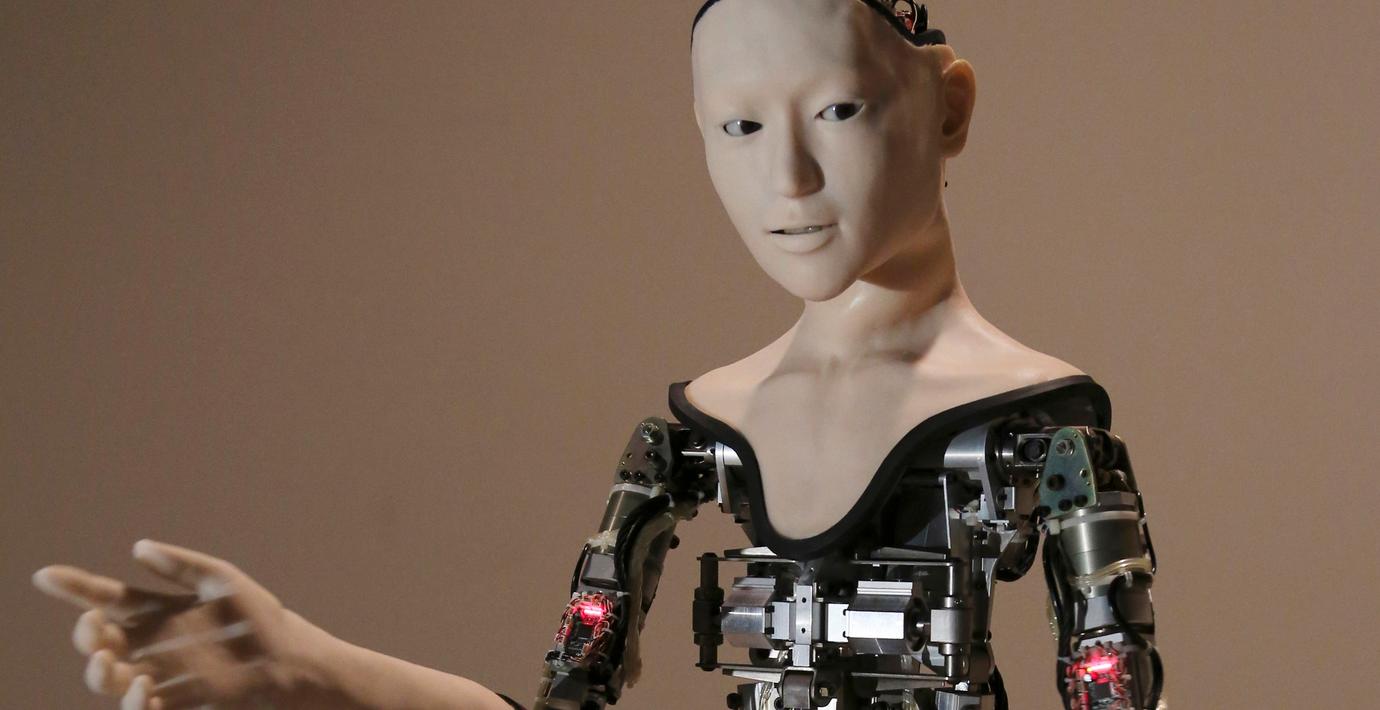

A cobot or co-robot (from collaborative robot) is a robot intended to physically interact with humans in a shared workspace. This is in contrast with other robots, designed to operate autonomously or with limited guidance, which is what most industrial robots were up until the decade of the 2010s.

Cobots were invented in 1996 by J. Edward Colgate and Michael Peshkin, professors at Northwestern University. A 1997 US patent filing describes cobots as "an apparatus and method for direct physical interaction between a person and a general purpose manipulator controlled by a computer."

Cobots resulted from a 1994 General Motors initiative led by Prasad Akella of the GM Robotics Center and a 1995 General Motors Foundation research grant intended to find a way to make robots or robot-like equipment safe enough to team with people. The first cobots assured human safety by having no internal source of motive power. Instead, motive power was provided by the human worker. The cobot's function was to allow computer control of motion, by redirecting or steering a payload, in a cooperative way with the human worker. Later cobots provided limited amounts of motive power as well.

The General Motors team used the term Intelligent Assist Device (IAD) as an alternative to cobot, especially in the context of industrial material handling and automotive assembly operations. A draft safety standard for Intelligent Assist Devices was published in 2002. An updated safety standard was published in 2016.

Cobotics released several cobot models in 2002.

Universal Robots released its first cobot, the UR5, in 2008. In 2012 the UR10 cobot was released, and later a table top cobot, UR3, in 2015. KUKA's LBR iiwa was the result of a long collaboration with the German Aerospace Center institute. Rethink Robotics released an industrial cobot, Baxter, in 2012.

FANUC - the world's largest producer of industrial robots - released its first collaborative robot in 2015 - the FANUC CR-35iA with a heavy 35kg payload. Since that time FANUC has released a smaller line of collaborative robots including the FANUC CR-4iA, CR-7iA and the CR-7/L long arm version.

Cobots can have many roles — from autonomous robots capable of working together with humans in an office environment that can ask you for help, to industrial robots having their protective guards removed as they can react to a human presence under EN ISO 10218 or RSA BSR/T15.1.

Omni är politiskt obundna och oberoende. Vi strävar efter att ge fler perspektiv på nyheterna. Har du frågor eller synpunkter kring vår rapportering? Kontakta redaktionen